For Brushless DC motor roller (For BLDC motor)

Feature

This device is a unit that controls a conveyor driven by a power-saving DC brushless motor with reduced wiring.

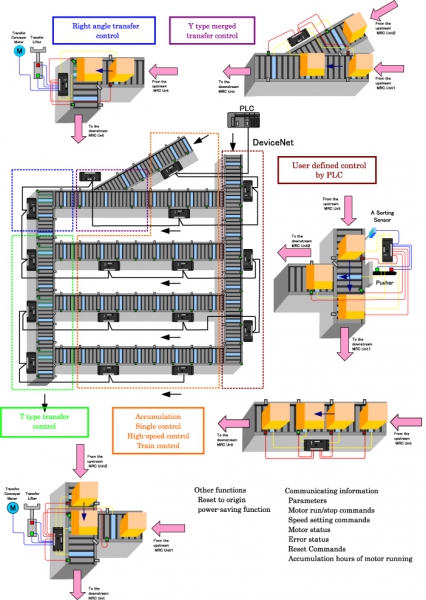

Equipped with various operation modes as standard, you can build a transfer line without a program.

It supports CC-Link and can be controlled by the user from the PLC.

By controlling four motor rollers at the same time, space saving, low price, and high functionality are realized.

Specification

Sample System Configuration

General specifications

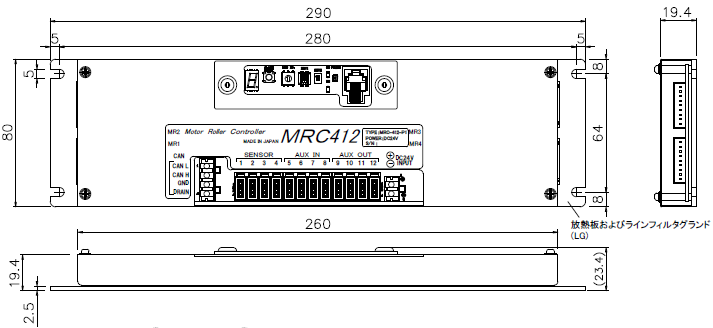

| Type | MRC-412 series /MRC-413 series |

|---|---|

| Power supply | DC24V±10% |

| Operation mode | No accumulation Accumulation Merge mode Right angle transfer control T-type transfer control |

| Other functions |

Same rotation Reset to origin Power saving |

| Transmission information |

Parameters Motor operation Speed control commands Motor status Error status Reset commands Operating time |

| External dimensions |

290(W)×23.4(D)×80(H) |

| Operation ambient environment |

Temperature -25~50℃(-13~122 deg F) Humidity 90% or less |

| Installation place | Indoor (without sunlight, rain, condensation and corrosive gas) |

Outline

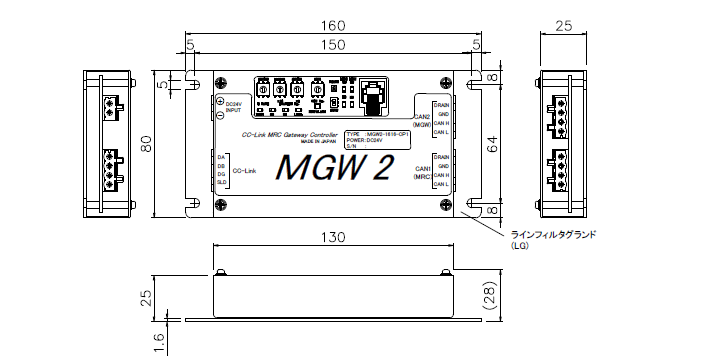

Gateway for MRC: MGW

| Type | MGW2-1616-CP1 |

|---|---|

| Power supply | DC24V±10% |

| I/F | CC-Link/Private Network(CAN) |

| Operation ambient temperature |

0~50℃(32~122 deg F) |

| Operation ambient humidity |

90% or less |

| Installation place |

Indoor (without sunlight, rain,condensation and corrosive gas) |